Capabilities & Services

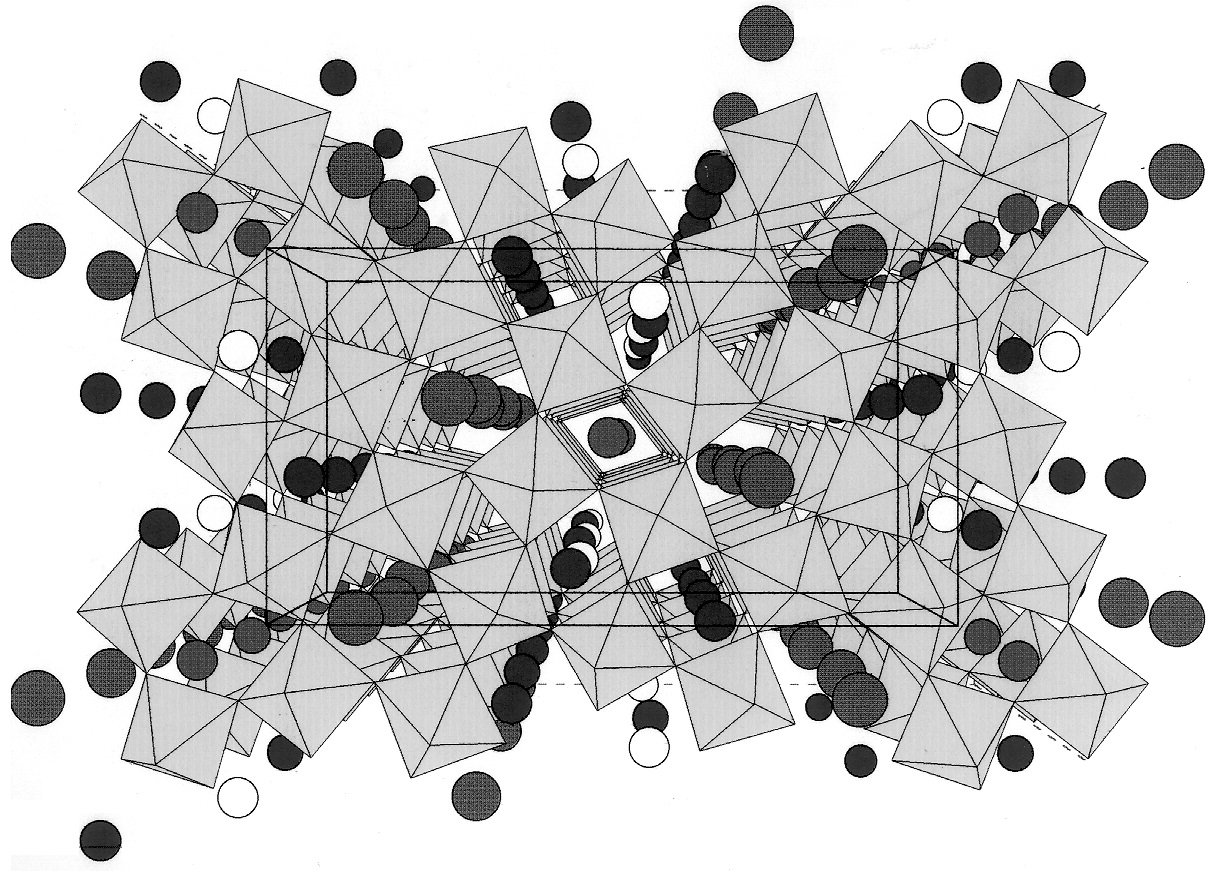

perovskite stucture

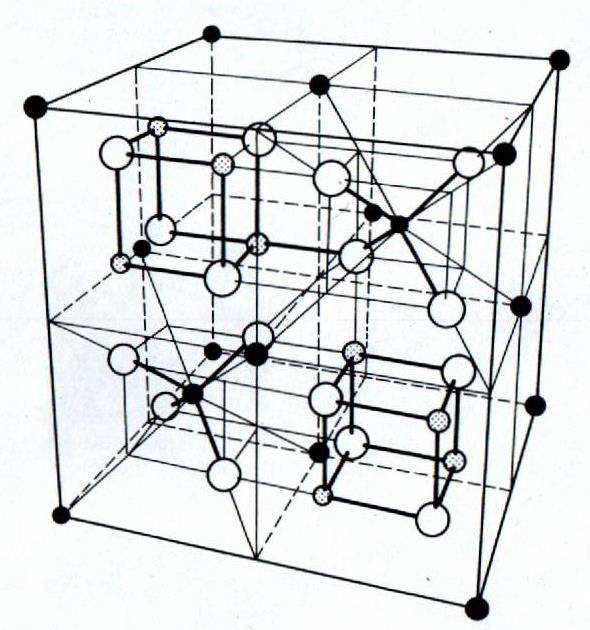

spinel structure

blended powder

spray dryer

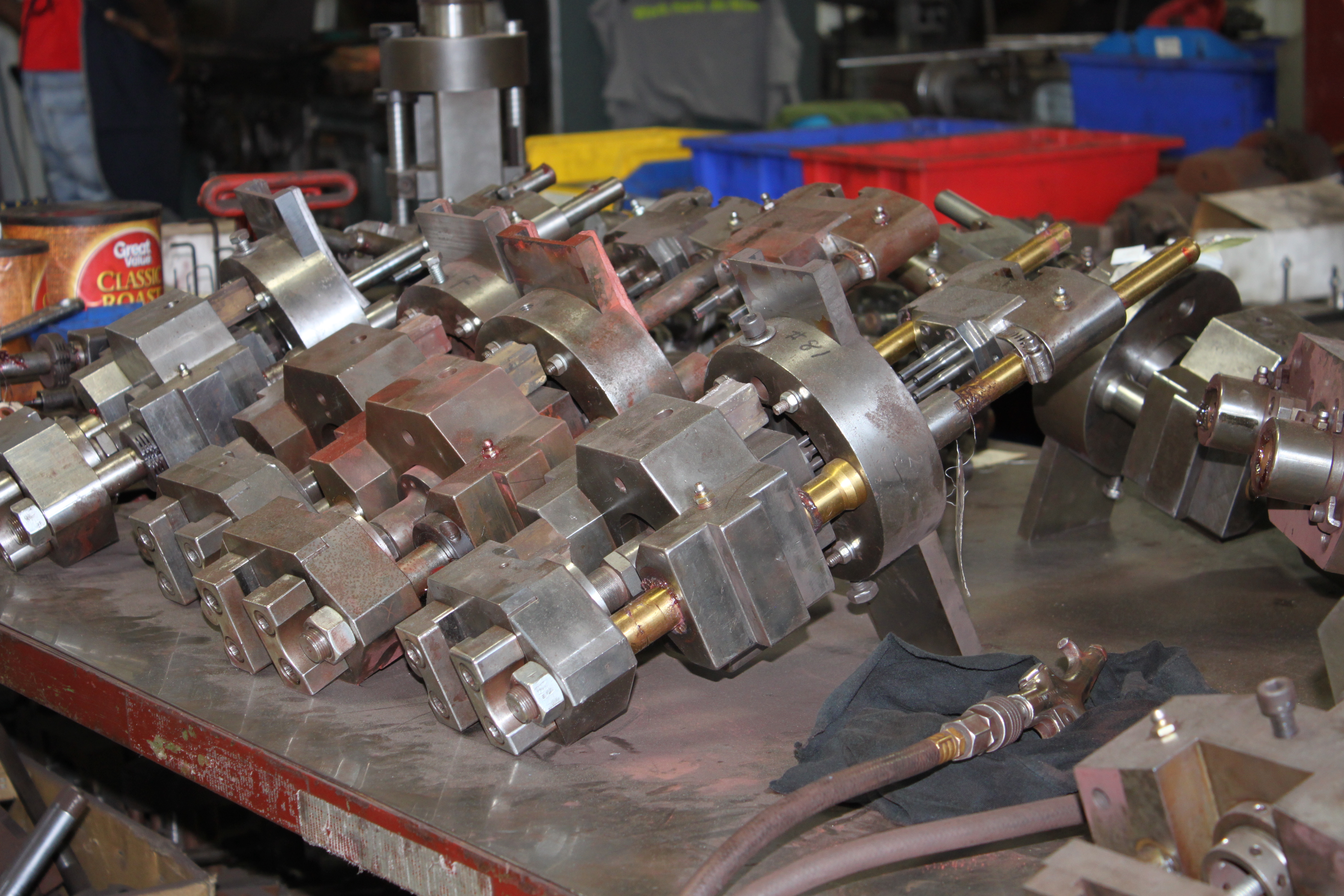

tool die sets

tooling

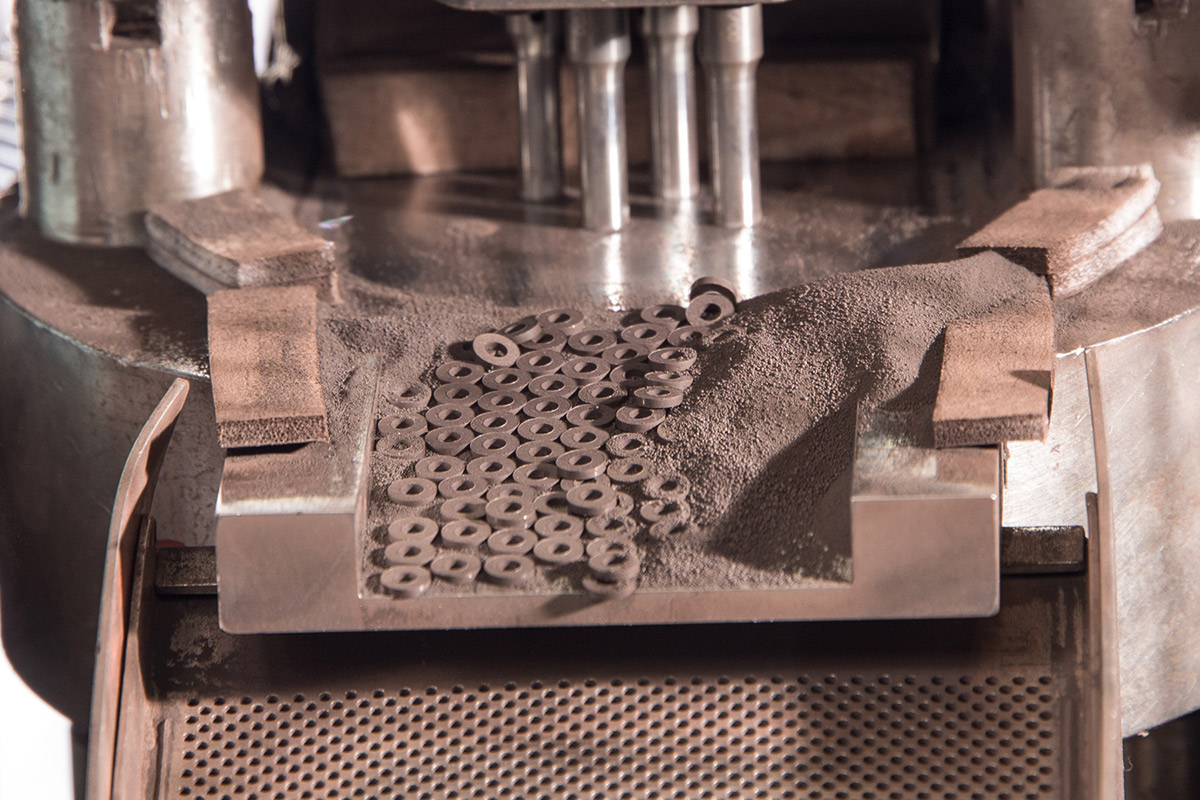

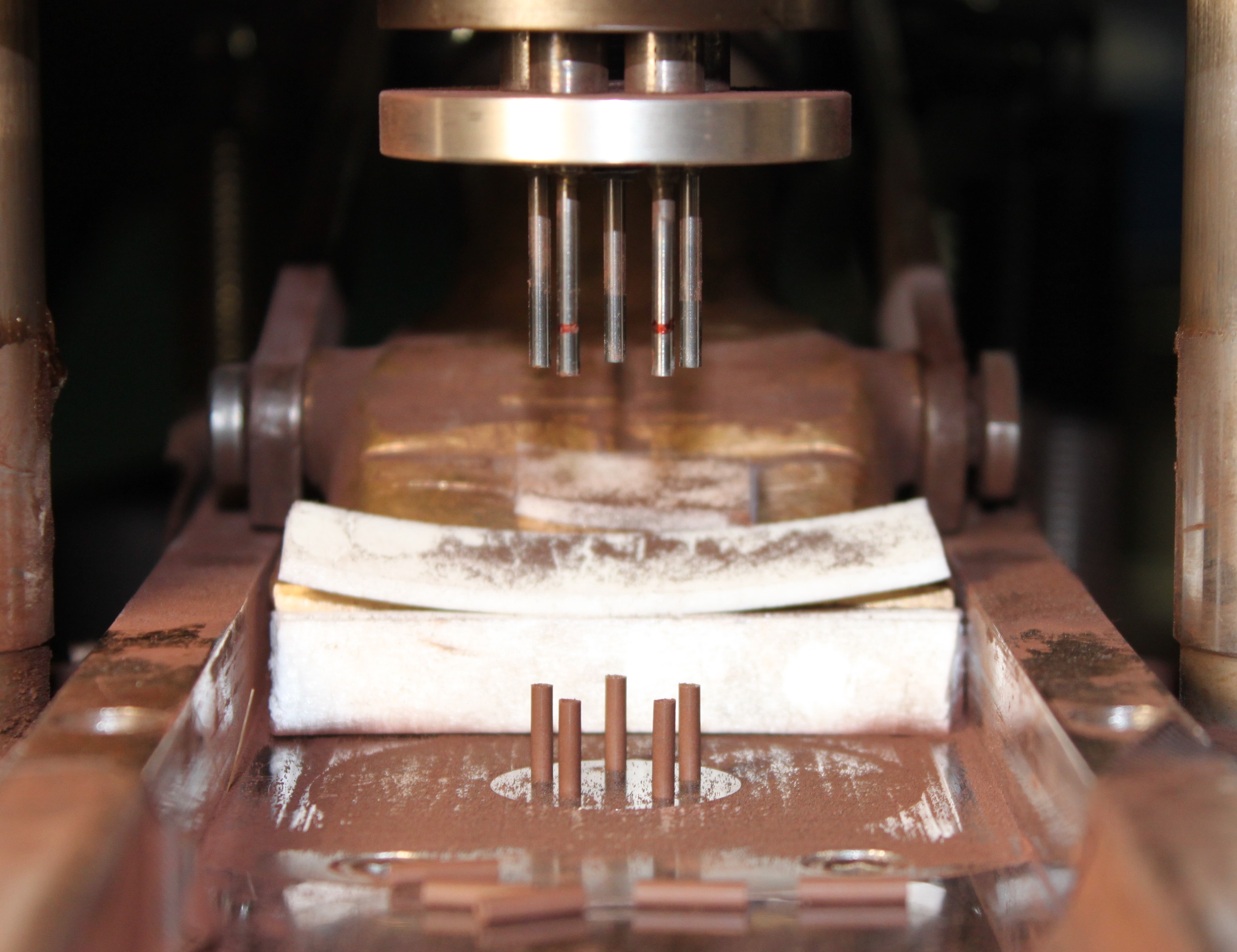

die pressing (4 cavity)

die pressing (5 cavity)

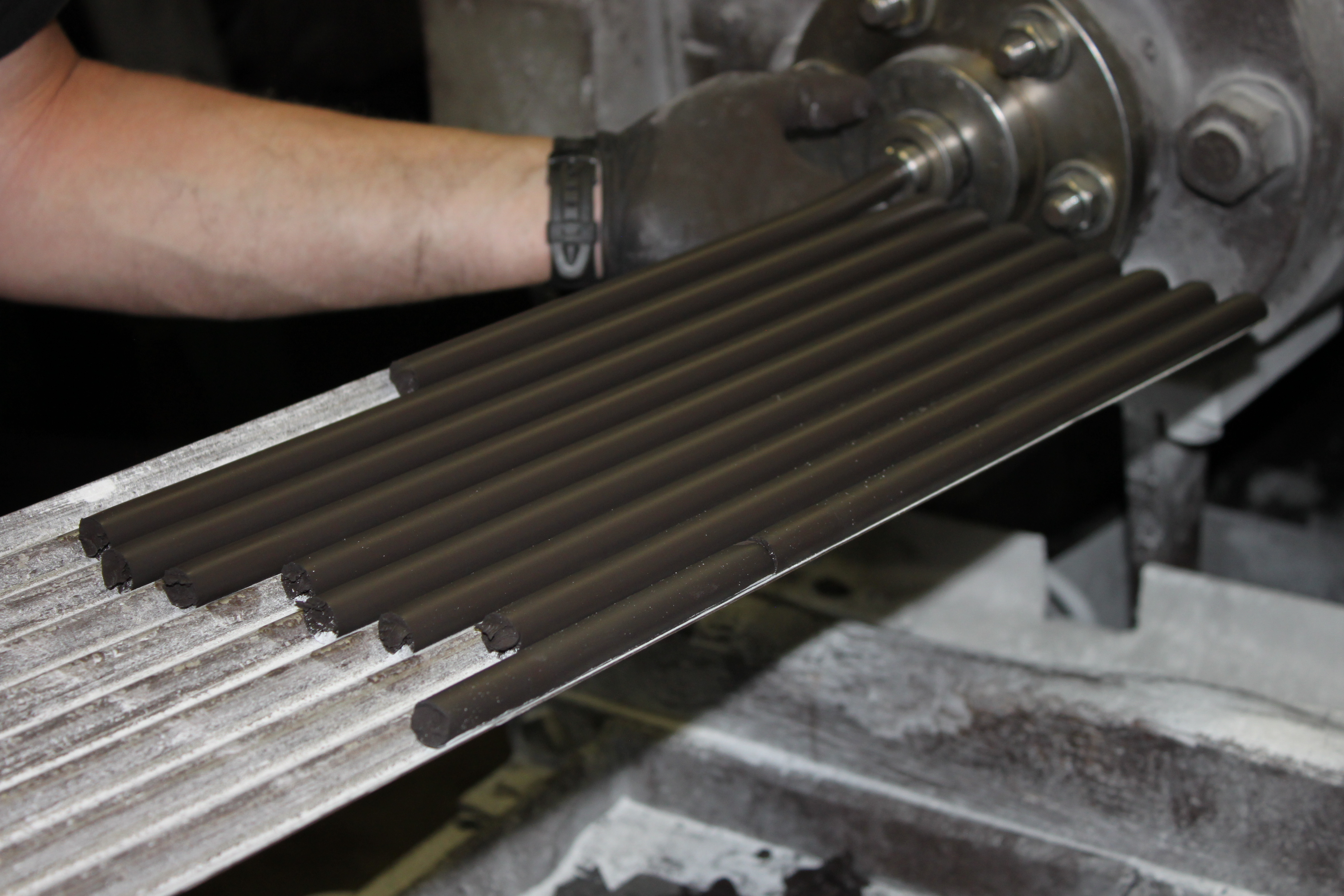

extruding rods

parts exiting tunnel kiln

parts after batch firing

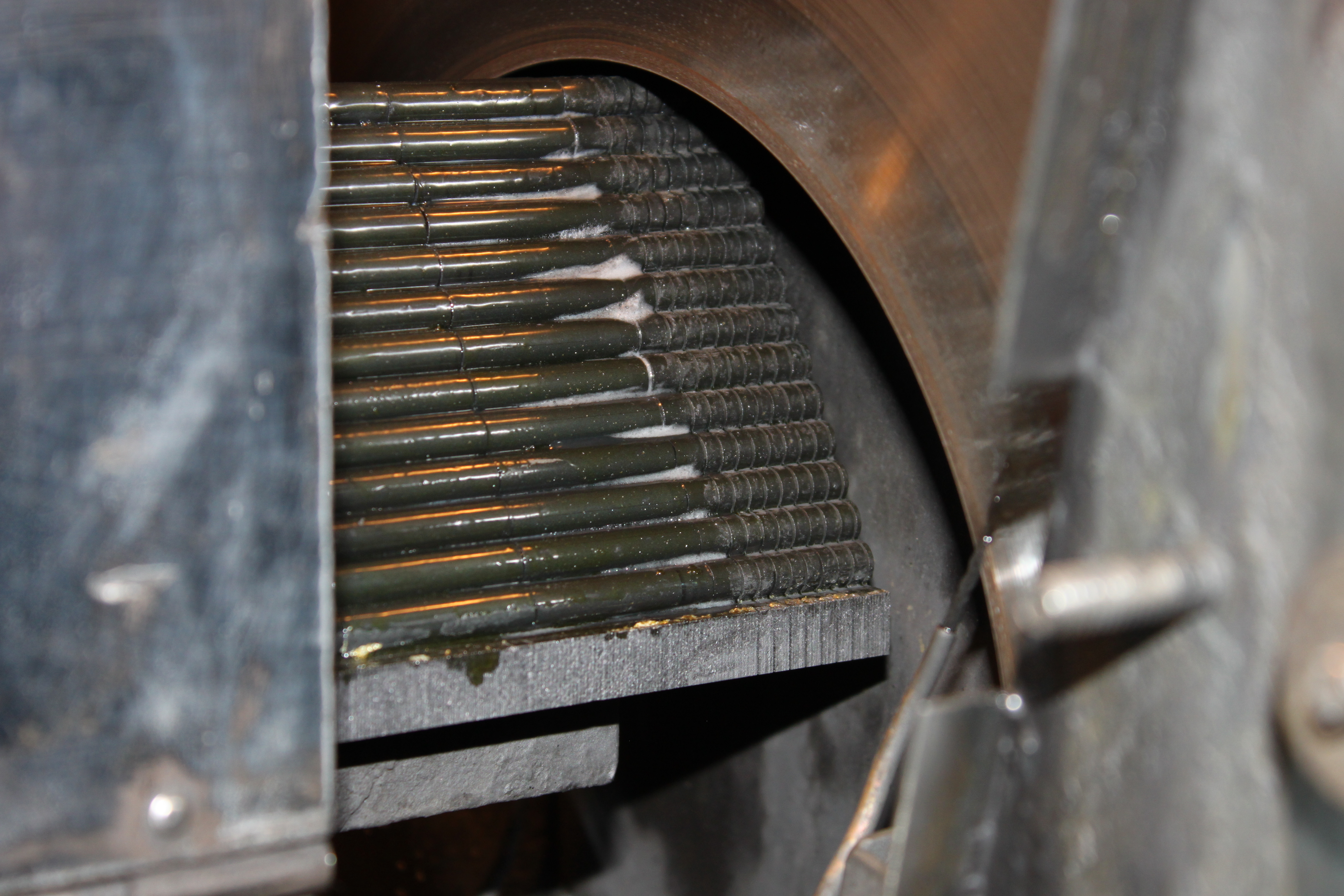

centerless grinding

single disc grinding

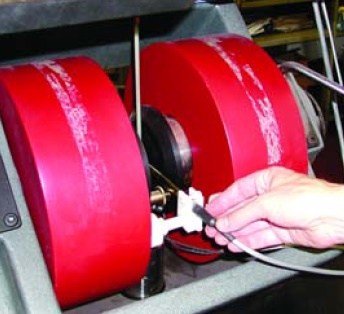

centerless grinding

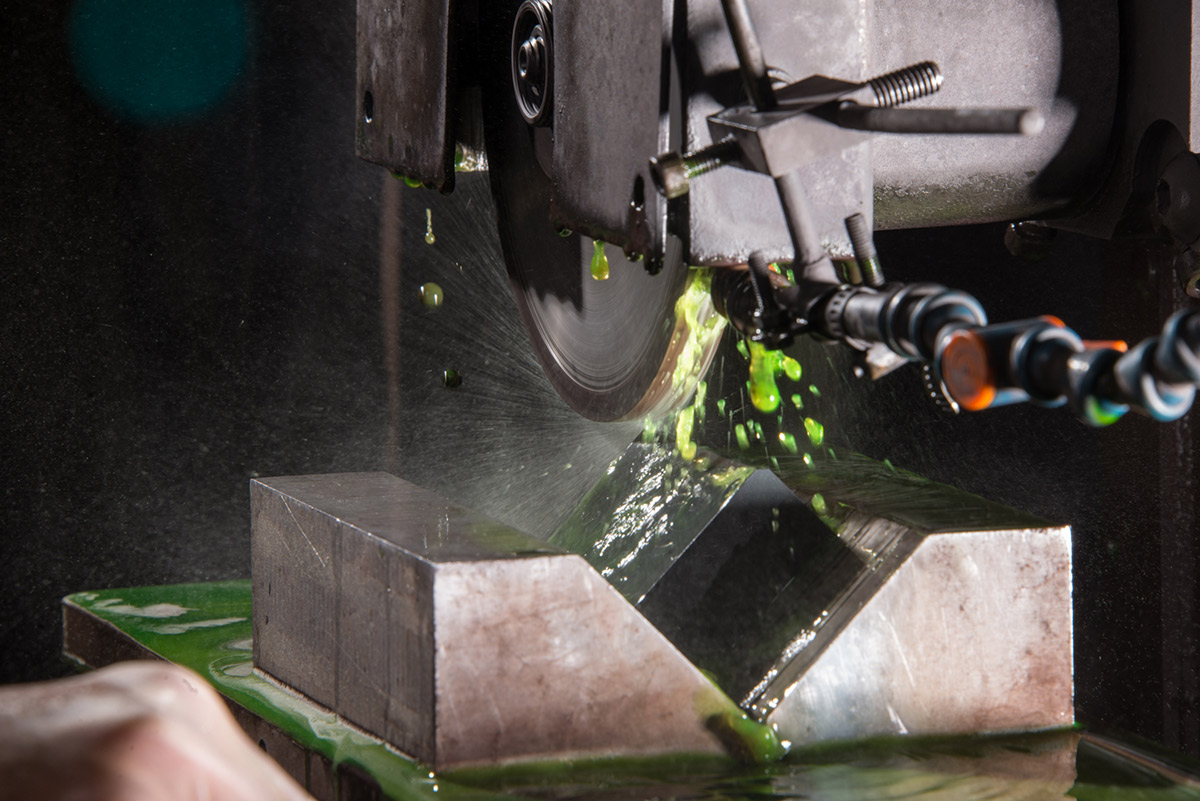

surface grinding

ID slicing

ID grinding

part testing

material testing

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

Through the offerings of our five Divisions, our capabilities run the gamut – we make parts from 0.016 (0.4mm) to 40.0 (1,016mm) inches in diameter. We are able to handle all aspects of material formulation (R&D through production), tooling, forming, sintering, machining, as well as the diverse offerings of our secondary operations. We have experienced Sales Engineers available to assist in determining the feasibility of using our products in your design. If you would like to contact a representative about a feature/offering we do not have listed (or have an inquiry on our offerings), fill out our contact form here. Or simply call our office.

Raw Material Production

- Blending/Mixing/Screening/Classifying

- Particle Size Reduction

- Calcining

- Drying

Tooling

- Complete in-house capability using high-speed tool steel and sintered carbide

Forming

- Mechanical Pressing

- Extrusion

- Cold Isostatic Pressing (CIP)

- Molding

Sintering

- Gas & Electric Atmosphere Controlled Tunnel Kilns

- Electric Atmosphere Controlled Batch Kilns

Value Added Operations

- Grinding

- Slicing

- Lapping

- Polishing

- Hot Isostatic Pressing

- Magnetizing

- Automatic & Manual Electrical Sorting/Grading

- Annealing (Magnetic and Thermal)

- Tumbling: Edge Rounding

- Marking/Color Coding

- Coating (Parylene and Other)

- Assembly, Gluing, Winding, Lead Insertion

- Packaging (Tape and Reel)

Inspection

- Powder Morphology

- Magnetic Property Testing/Analysis

- Microstructure Analysis

- Dimensional

Research & Development

- Material Formulation and Characterization